| ʻAno kila | ʻO ke kila kila: |

| Kūlana |

|

| Nā kikoʻī hana | Paʻa kila, Pepa, Coil, Paʻa paʻa, Paʻa pōʻai, Kāohi kila, uwea, ʻO nā ʻano forgings āpau. |

| Mchining | Huli Milling Ka wili ʻana ʻO ka wili lua hohonu: ka lōʻihi max 9.8 mika. |

| Ka laulā o ka hana | Ke kila lāʻau pōʻai: 1mm a 2000mm Ke kila ʻano huinaha: 10mm a 1000mm kila Pā / pepa: 0.08mm i 800mm Laulā: 10mm a 1500mm Lenth: Hiki iā mākou ke hoʻolako i kekahi lenth ma muli o ka koi o ka mea kūʻai. Ka hana ʻana: ʻO nā kumu me nā ʻaoʻao / paipu / paipu / slugs / donuts / cubes / ʻano ʻano ʻē aʻe ʻO nā paipu: OD: φ4-410 mm, me ka mānoanoa pā mai ka 1-35 mm. |

| Hoʻoponopono wela | Normalizing, Annealing, Tempering, Quenching, Hardening and Tempering, Seasoning, Surface hardening, Carburizing |

AWS E10015-D2 KĀMĀKĀWAI A ME KA MEA MEKANIKAL:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | 'ē aʻe |

NA WAIWAI MECHANICAL:

| Waiwai | Nā kūlana | ||

| T (°C) | Lapaʻau | ||

| ʻOi (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Ka ratio o Poisson | 0.27-0.30 | 25 |

|

| Modulus Elastic (GPa) | 190-210 | 25 |

|

| Ikaika U'i (Mpa) | 1158 | 25 | ʻaila kinai ʻia, kānana maikaʻi, hoʻoluliluli ʻia ma 425 ° C |

| Ka ikaika hua (Mpa) | 1034 | ||

| Elongation (%) | 15 | ||

| Hoemi ma kahi (%) | 53 | ||

| Paʻakiki (HB) | 335 | 25 | ʻaila kinai ʻia, kānana maikaʻi, hoʻoluliluli ʻia ma 425 ° C |

| Waiwai | Nā kūlana | ||

| T (°C) | Lapaʻau | ||

| ʻO ka hoʻoili wela (W/mK) | 42.7 | 100 | |

| Wela Kūikawā (J/kg-K) | 477 | 50-100 | |

NA WAIWAI KINO:

| Ka nui | Waiwai | Unite |

| Hoʻonui wela | 16 - 17 | e-6/K |

| ʻO ke kau wela wela | 16 - 16 | W/mK |

| wela kūikawā | 500 - 500 | J/kg.K |

| He wela wela | 1370 - 1400 | °C |

| Wela lawelawe | 0 - 500 | °C |

| ʻO ka mānoanoa | 8000 - 8000 | kg/m3 |

| Kū'ē | 0.7 - 0.7 | ʻOhm.mm2/m |

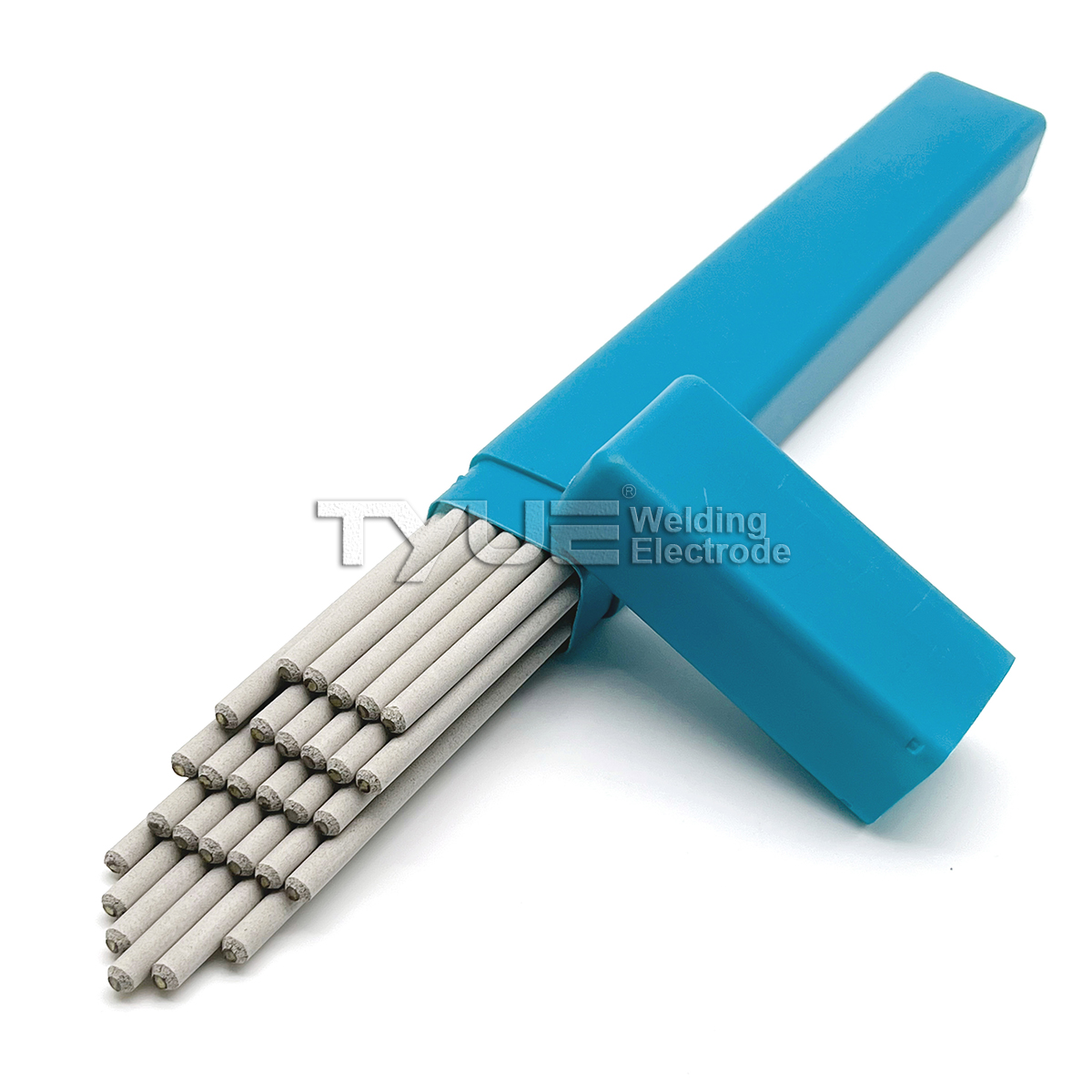

E7015-G Haʻahaʻa Hydrogen Sodium Coating Welding Electrodes

DESCRIPTION:

He koʻokoʻo kuʻihao haʻahaʻa haʻahaʻa me ka paʻakai hydrogen haʻahaʻa me ka nickel.Hiki ke hoʻokō ʻia ka wili kūlana piha e ka pilina pili dc.I loko o -80°C weld metala i loaʻa i ka paʻakikī hopena maikaʻi.

Hoʻohana:

Welded -80 ° C hana 1.5Ni hana kila.

METAL CHEMICAL COMPOSITION:

| C | Mn | Si | Ni | S | P | |

| Kūlana | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Hoao | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

HANA MECHANICAL METAL DEPOSITED:

| Ikaika U'i Rm (MPa) | ʻO ka rel o ka ikaika hua (MPa) | Elongation A (%) | -80°C Ka Waiwai Akv (J) | |

| Kūlana | ≥490 | ≥390 | ≥22 | ≥27 |

| Hoao | 530 | 445 | 30 | 100 |

KA MANA HOʻOPIʻI (DC+):

| Anawaena (mm) | 3.2 | 4.0 | 5.0 | |

| Ka lōʻihi (mm) | 350 | 400 | 400 | |

| I kēia manawa (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Wahi a GB E8515-G E pili ana me AWS E12015-G |

Introduction: ʻO E12015-G kahi ʻano haʻahaʻa haʻahaʻa haʻahaʻa kiʻekiʻe ikaika kila electrode me ka haʻahaʻa-hydrogen natrium type coating.ʻO DCRP (Polarity Hoʻohuli pololei i kēia manawa).wiliwili kūlana āpau.

Hoʻohana: Hoʻohana ʻia no ka hoʻopaʻa ʻana i nā hale kila kiʻekiʻe me ka ikaika tensile e pili ana i 830MPa.

Hoʻohui Kimia o ka Metala i waiho ʻia (%)

| Hoʻohui Kimia | C | Mn | Si | S | P | Mo |

| Waiwai Hōʻoia | ≤0.15 | ≥1.00 | 0.4-0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Hua nui | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Na Mea Mekanika o ka Metala I Waihoia

| Mea hoao | Rm(MPa) | ReL pahaRp0.2(Mpa) | A(%) | KV2(J) |

| Waiwai Hōʻoia | ≥830 | ≥740 | ≥12 | —(mahana maʻamau) |

| Hua nui | 860~950 | ≥750 | 12-20 | ≥27 |

Maʻiʻo Hydrogen Diffusible i loko o ka metala i waiho ʻia: ≤5.0ml/100g(Chromatography)

X-ray Radiographic Inspection: ⅠDegree

OLELO HOOLAHA:

1. Pono e hoʻomoʻa ʻia nā electrodes ma lalo o 350-400 ℃ no hoʻokahi hola ma mua o ke kuʻi ʻana, e hoʻokomo i loko o kahi pahu insulation a hoʻopili koke i ka wā e pono ai.

2. Pono e hoʻomaʻemaʻe ʻia nā stains ma ka weld e like me ka rust, a pono e hoʻomaʻamaʻa ʻia ka weld ma kahi o 200 ℃.

3.Weld hiki ke hoʻonāukiʻia ma lalo o 600-650 ℃ ma hope o ka wiliʻana i mea e hoʻopau ai i ke kaumaha o loko.