Nikala a me ka Nickel AlloyKuʻihaoʻElekoda

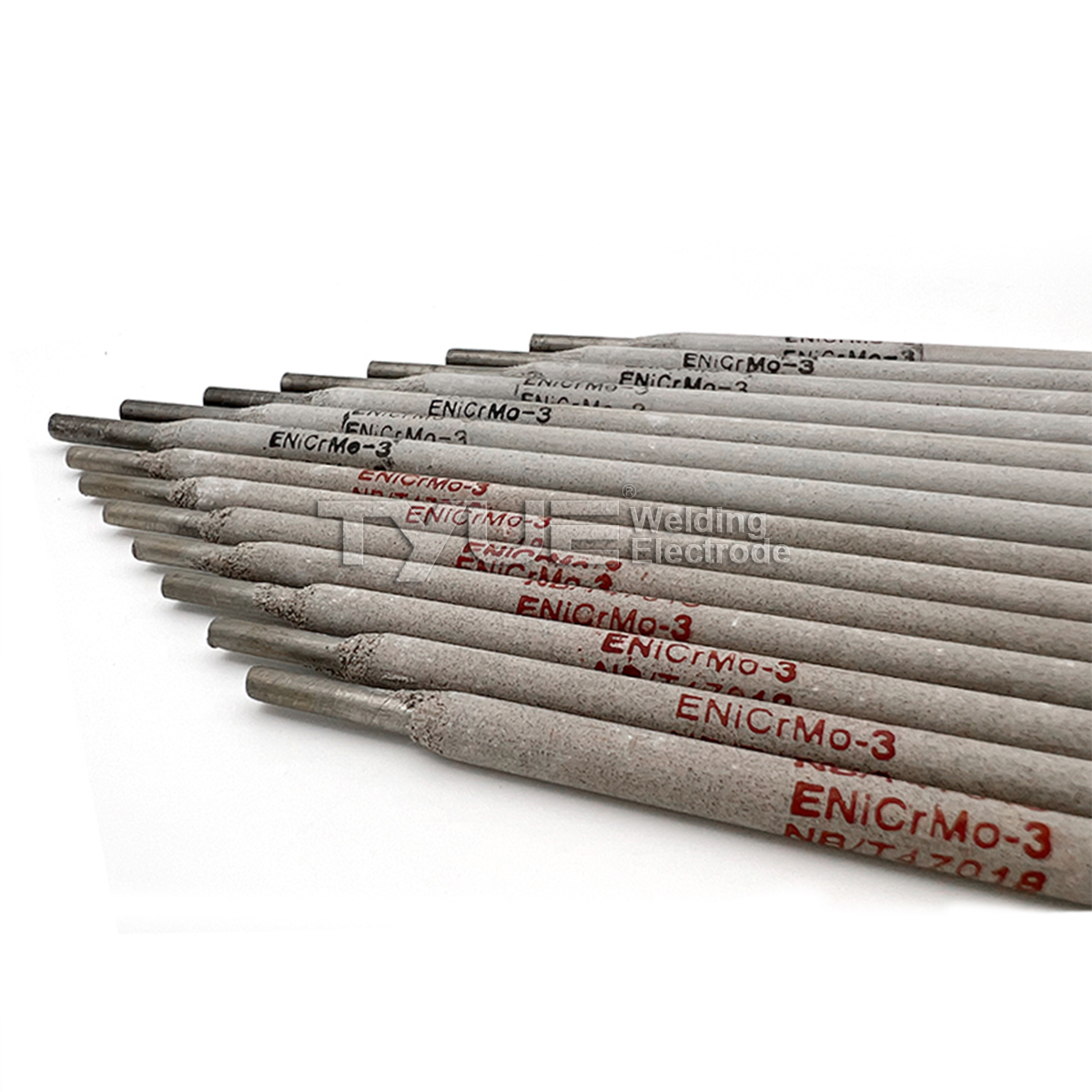

Ni327-3

GB/T ENi6625

Wehewehe: ʻO Ni327 -3 kahi electrode nickel me ka uhi sodium haʻahaʻa-hydrogen. E hoʻohana i ka DCEP (electrode au pololeimaikaʻi). Loaʻa i ka metala i waiho ʻia ka plasticity maikaʻi loa, ka paʻakikī a me ke kūpaʻa i ka māwae, a he ikaika kiʻekiʻe a me ke kūpaʻa ikaika i ka pala i ka mahana o ka lumi a me ke kiʻekiʻe o ka mahana.

Noi: Hoʻohana ʻia no ka hoʻopili ʻana i nā mea hoʻohuihui nickel-chromium-molybdenum, ʻoi aku ka hoʻopili ʻana a me ka ʻili ʻana o nā mea hoʻohuihui UNS N06625 a me nā ʻano kila ʻē aʻe a me nā kila hui nickel-chromium-molybdenum, a hiki ke hoʻohana ʻia no ka hoʻopili ʻana i ke kila Ni9% ma lalo o nā kūlana mahana haʻahaʻa.

Ka hoʻohuihui kemika o ka metala i hoʻoheheʻe ʻia (%):

| C | Mn | Si | Cr | Ni | Mo |

| ≤0.10 | ≤2.0 | ≤0.8 | 20.0 ~ 23.0 | ≥55.0 | 8.0 ~ 10.0 |

| Fe | Cu | Nb + Ta | S | P | ʻĒ aʻe |

| ≤7.0 | ≤0.5 | 3.0 ~ 4.2 | ≤0.015 | ≤0.020 | ≤0.5 |

Nā ʻano mechanical o ka metala i hoʻoheheʻe ʻia:

| Mea hoʻāʻo | Ikaika tensile Mpa | Ikaika hāʻawi Mpa | Hoʻolōʻihi % |

| Hōʻoiaʻiʻo ʻia | ≥760 | ≥420 | ≥27 |

Manaʻo ʻia kēia manawa:

| Anawaena o ke koʻokoʻo (mm) | 2.5 | 3.2 | 4.0 |

| Au wili (A) | 50 ~ 70 | 80 ~ 100 | 110 ~ 150 |

Hoʻolaha:

- Pono e hoʻomoʻa ʻia ka electrode no 1 hola ma kahi o 300℃ ma mua o ka hana kuʻihao. E hoʻāʻo e hoʻohana i kahi arc pōkole e kuʻihao ai;

- He mea nui e hoʻomaʻemaʻe i ka ʻōpala, ka ʻaila, ka wai, a me nā mea haumia ma nā ʻāpana kuʻihao ma mua o ka kuʻi ʻana.

3. E hoʻāʻo e hoʻohana i ka ikehu laina liʻiliʻi i ka wā e kuʻi ai, ka kuʻi multi-layer a me ka multi-pass.